Our Low-Carbon Future

Reflections from the RIBA Low-Carbon Future conference in Exeter.

Wapan House using reclaimed materials.

It was a packed day of presentations, case studies, and conversations about how our industry is working toward delivering a low-carbon built environment. I had been invited to present; I shared a bit about Barefoot’s process and how this has led to some very pioneering and inspiring projects. I talked about our Chalk House and how it's self-build nature allowed for experimentation and recycling of site/construction materials reducing waste to nearly zero. Our Wapan Houses that use reclaimed materials to create beautiful cladding as well as the exceptional, low-carbon construction of a converted farmhouse and a pair of some semi-subterranean homes. I also presented our Bridport cohousing scheme and discussed the (carbon) merits of more communal living - how sharing resources and facilities can reduce both upfront and whole life cardon. It seemed to be received very well and it was great to remind myself of the great work we do (as we are always talking about how we can do better)!

The rest of the talks were also great and I must admit, I felt a bit like the class geek - often being the first to ask a question of almost every speaker! But that’s exactly why events like this are so valuable: the chance to listen, question, and challenge – and to leave with a notebook full of ideas and reflections. Big thanks to the organisers, speakers and attendees!

At the bottom of the blog there’s a sped-up video of my presentation for anyone interested… and here's a few cherry-picked take-aways of mine from other talks:

Conflicting challenges

A big-picture theme was the alignment (or misalignment) of planning policy and general industry carbon-reduction goals - the lack of central government leadership to unify different regional approaches and also the alignment of client budgets and architects' ambitions. There was lots of discussion around South Hams’ pioneering but controversial Climate Emergency Planning Statement - M5 policy, which requires evidence of carbon payback for a 'knock-down, rebuild' project. It was fascinating to hear how differently people are responding to it – some finding it an impossible hurdle, and others (like us) seeing it as entirely reasonable and frankly just good, forward-thinking common-sense. We’d love to see this kind of thinking become the norm across more local authorities.

Measuring issues

The difficulty of calculating embodied and whole-life carbon came up repeatedly. It’s encouraging to see so many practices trying to get to grips with this, though the lack of easily accessible tools or cost of consultant input seems to remain an obstacle. I was impressed (and slightly alarmed) to learn that Studio Bark have gone as far as developing their own carbon calculation tool (with funding from Innovate UK) called SmallCarbon. We’ve talked about this at Barefoot too - developing a simplified tool that interfaces with our CAD system for assessing embodied carbon at early design stages - so it just highlights how necessary simple, design-focussed tools are and how software packages are not working for smaller practices. South Hams has tried to combat this with a free tool (spreadsheet) called Mesh to assist with M5 applications

Material science

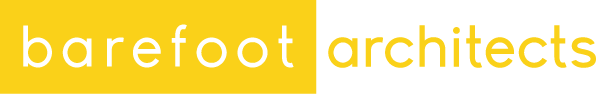

There were some brilliant deep-dives into material performance - from lessening the 'evils' of concrete to natural products like hemp, cobb and woodfibre. We already use and specify wood fibre insulation regularly, but I came away with new appreciation for its thermal mass and decrement delay qualities - the way it slows heat transfer through the building fabric, helping maintain stable internal temperatures through day and night. There was also a sobering factoid around installer and occupant health regarding the off-gassing from PIR foams and formaldehyde binders in many mineral wool products. It’s reassuring that our eco material choices remain industry-leading in terms of healthier, low-carbon options. Hemp and other grass products are also gaining traction – we’ve used hempcrete a few times already but there was a hemp cladding panel from Hemspan shown that caught my attention too!

Decrament delay of different insulations.

Another standout was a presentation on a Passivahus building using monolithic clay block wall construction - used without external insulation. The 365mm thick clay block (internally plastered and externally clad) achieves around 0.25 W/m²K and although this is nothing to write home about, the beauty of it is the simple, fast construction with an easy thermal-bridge-free detail at the plinth, and the way it regulates humidity and vapour movement naturally. It’s a great reminder that innovation doesn’t always mean new/complex technology – sometimes it’s about re-evaluating traditional materials for modern performance standards.

Monolithic clay wall.

Listen, learn and lead.

Days like this are a reminder that small-practice’s transition to a low-carbon future is both complex and exciting. There’s no single solution - but by sharing knowledge, pushing new ideas, and asking lots of questions, we can help move things in the right direction.